Applications of FRP Pultruded Gratings

Top Applications of FRP Pultruded Gratings in Indian Industries

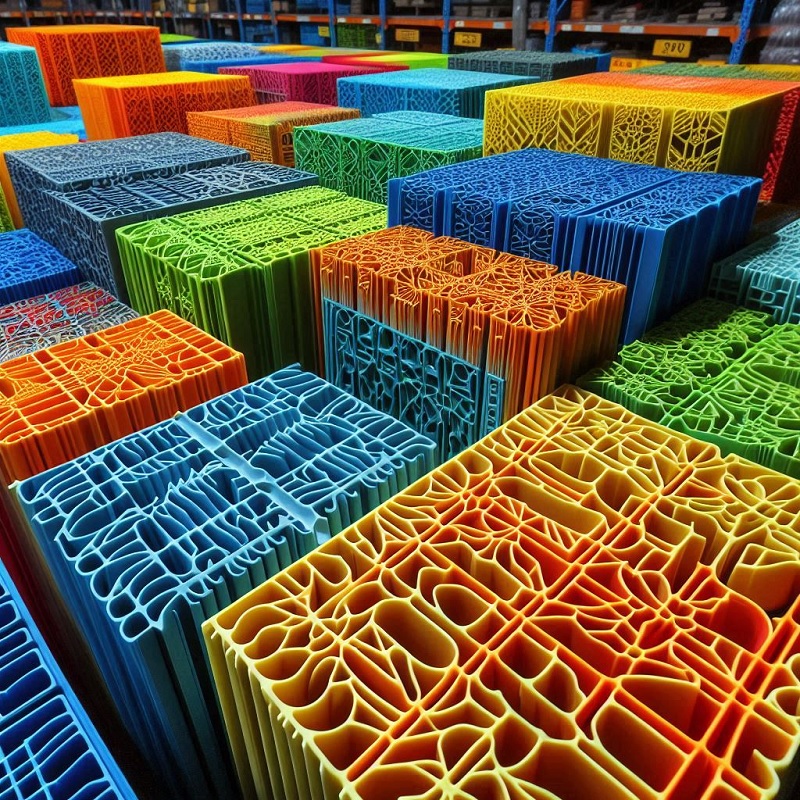

The government of India recommended the use of FRP pultruded gratings across many industries due to its strength, corrosion resistance and long service life. In the power and energy sector, FRP gratings provide reliable transformer platforms, walkways, and sets of cable trench covers thanks to its non-conductive and fire-retardant properties. Chemical and petrochemical plants rely on FRP gratings because of the flooring and access structures that can withstand exposure to aggressive chemicals. Waste Water treatment and water management infrastructures are relying on FRP pultruded gratings to provide rust free, slip resistant surfaces in constantly wet conditions. The marine and offshore industries are also using FRP pultruded gratings for saltwater resistant, and UV protection. FRP pultruded gratings have even found use in telecommunications and transportation as non-conductive, low maintenance access platforms and structural supports. Overall, as a building material, pultruded FRP gratings have become truly ubiquitous across multiple industrial sectors both in Canada and India.

Why FRP Pultruded Gratings Are the Preferred Choice for Heavy-Duty Projects in India

FRP pultruded gratings India is the best option for heavy duty projects in India because they offer superior mechanical strength and long life in extreme applications. Unlike with metal gratings, FRP pultruded grating does not have the risk of corrosion. FRP pultruded gratings, are a lightweight, non-conductive material that can be used in a number of industries such as oil & gas, power generation, chemical processing or marine infrastructure. FRP pultruded gratings will provide high load bearing capabilities, structural rigidity and the ability to allow normal foot traffic without warping or degrading. FRP pultruded gratings are extraordinarily low maintenance, are fire resistance, UV resistance, chemical resistant. FRP is a long term reliable and cost effective solution for infrastructure applications requiring safety and performance in extremely designed vigours and environmental conditions.

Choosing the right FRP pultruded grating supplier in India

Choosing a quality FRP pultruded grating supplier in India is essential to ensure that you get reliability, performance and in the end value, for your industrial applications. An experienced manufacturer should provide many types of grating to suit your load, geographic, environmental considerations, with appropriate industrial specifications. For example, it is reasonable to expect that a supplier will have their own internal pultrusion capability, have the best quality certifications (ISO or ASTM) to ensure privacy, have the reasonable capability of delivering products consistently and allowing reasonable lead times and in all probability have a well established track record. A company capable of delivering customization, technical support, and responsive after sale service, is usually a reliable partner to work with. Working with a quality FRP pultruded grating supplier in India, will give you the assurance of product quality and a level of comfort for executing your projects throughout.