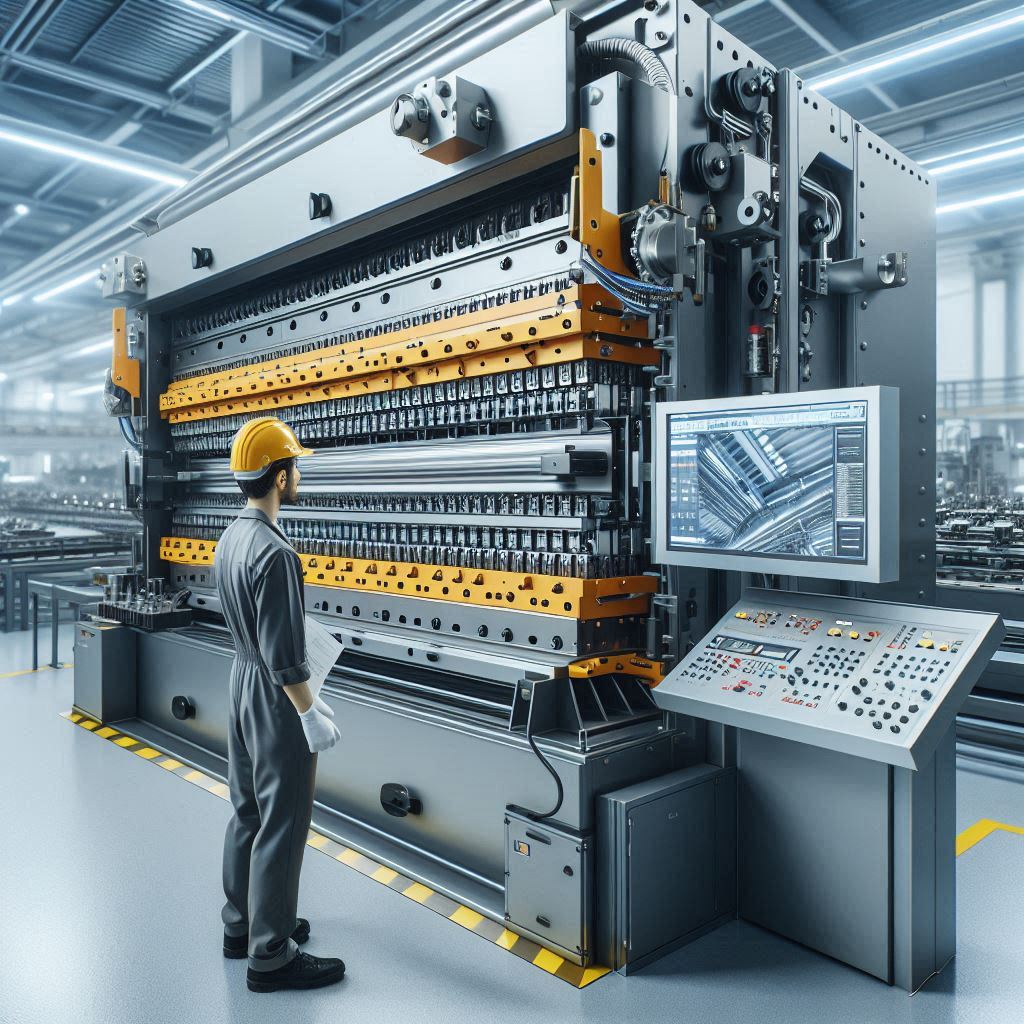

Hydraulic Plate Bending Machines Transform Fabrication

Hydraulic plate bending machines are revolutionizing metal

fabrication by combining unmatched power, precision, and efficiency to shape

heavy-duty metal sheets with ease. Unlike traditional mechanical systems,

hydraulic benders use controlled fluid pressure to apply uniform force,

enabling consistent bends even in thick or high-strength materials. This

technology significantly reduces manual effort and material waste while

increasing productivity, making it indispensable in industries like

shipbuilding, construction, and heavy machinery manufacturing. With advanced

features such as CNC controls and programmable settings, modern hydraulic plate

bending machines are not just tools—they are intelligent systems driving

innovation and excellence in the fabrication process.

Understanding the Mechanics Behind Hydraulic Plate Bending Technology

Understanding the mechanics behind hydraulic plate bending

technology reveals how this powerful system transforms flat metal sheets into

precise curved shapes with minimal effort. At its core, the machine uses

hydraulic cylinders to generate immense pressure, which is applied through a

punch and die setup to bend the metal along a desired axis. The hydraulic

fluid, when pressurized, delivers consistent force that ensures smooth and

accurate bends, even on thick or complex materials. This controlled mechanism

not only enhances bending accuracy but also allows for repeatability in

high-volume production. By mastering this technology, operators can achieve

superior results in metal forming while optimizing efficiency and reducing wear

on tools.

From Shipbuilding to Structural Steel: Hydraulic Benders in Action

From shipbuilding to structural steel fabrication, hydraulic

plate bending machine is playing a pivotal role in shaping the backbone of

modern infrastructure. In shipyards, these machines are essential for forming

the large, curved hull sections that define a vessel’s strength and

hydrodynamics. Similarly, in the construction of bridges, high-rise buildings,

and industrial frameworks, hydraulic benders provide the precision and power

needed to manipulate thick steel plates into beams, braces, and custom

components. Their ability to handle diverse materials and complex bending

requirements makes them indispensable across heavy industries, where

durability, accuracy, and production speed are critical for success.