Choosing the Right FRP Pultruded Grating Manufacturer

Choosing the right FRP pultruded grating manufacturer is

essential to ensuring product durability, performance, and compliance with

industry standards. A reliable manufacturer will use high-quality raw

materials, such as corrosion-resistant fiberglass and premium resin systems,

and adhere to international benchmarks like ASTM and ISO. Look for suppliers

with a strong track record, modern pultrusion facilities, and the ability to

offer customized grating solutions tailored to your project’s load, size, and environmental

requirements. Transparent certifications, consistent product quality, on-time

delivery, and responsive customer service are all indicators of a trustworthy

partner in the FRP pultruded grating industry.

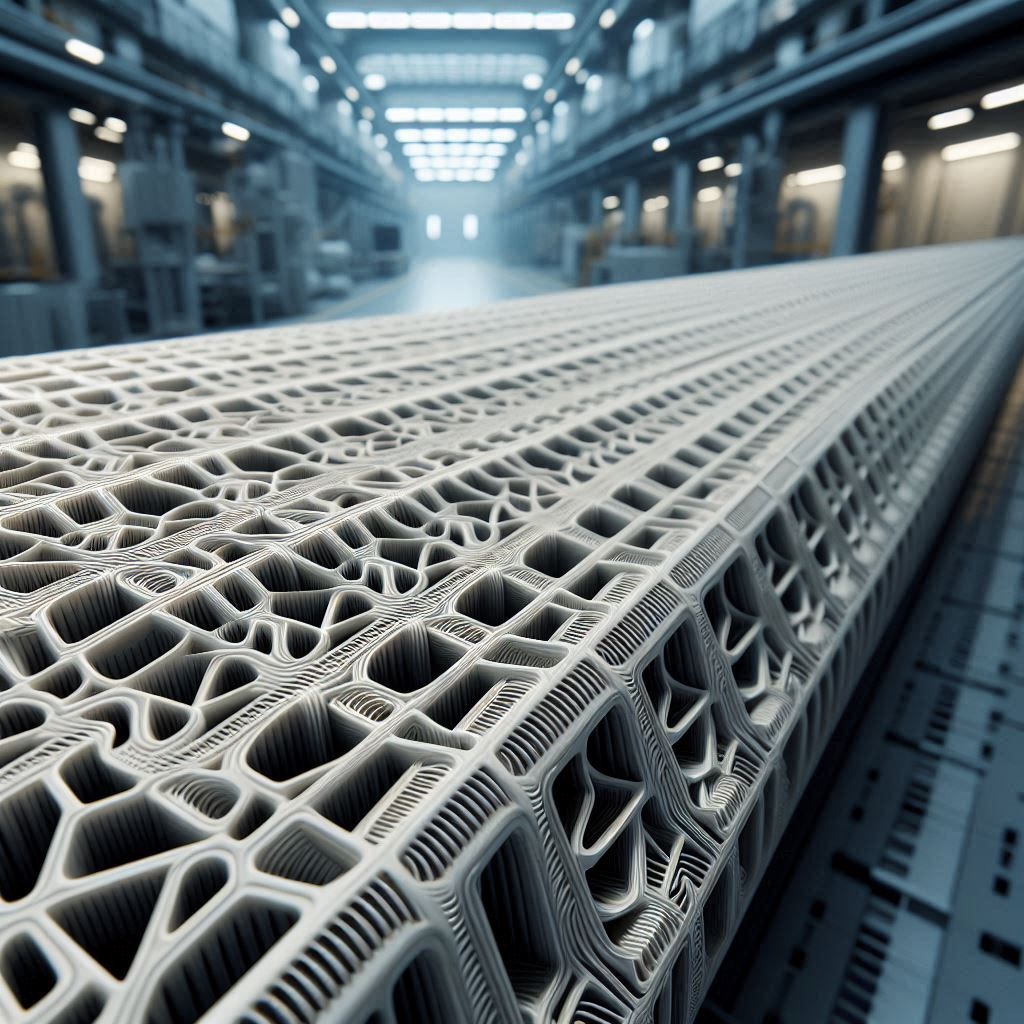

FRP Pultruded Gratings in Oil & Chemical Industries

FRP pultruded gratings are widely used in oil and chemical industries due to their exceptional corrosion resistance, high strength-to-weight ratio, and non-conductive properties. These gratings perform reliably in harsh, corrosive environments where exposure to chemicals, acids, and solvents is common—making them ideal for platforms, walkways, trenches, and overhead covers in refineries, chemical plants, and offshore rigs. Unlike metal alternatives, FRP pultruded gratings do not rust or deteriorate over time, reducing maintenance costs and ensuring long-term safety. Their high load-bearing capacity and fire-retardant characteristics further make them a preferred choice for demanding industrial applications.

Why FRP Pultruded Gratings Outperform Steel

FRP pultruded gratings outperform steel in many industrial applications due to their superior corrosion resistance, lightweight structure, and long-term durability. Unlike steel, which is prone to rust and chemical degradation, FRP gratings can withstand harsh environments—such as chemical plants, coastal areas, and wastewater facilities—without deteriorating. They are also non-conductive, reducing the risk of electrical hazards, and require minimal maintenance over time, lowering lifecycle costs. Additionally, FRP gratings are easier to transport and install due to their lower weight, yet still offer high tensile strength and structural integrity, making them a smarter, more cost-effective alternative to traditional steel solutions.

Conclusion

In conclusion, selecting the right FRP pultruded grating manufacturer is a critical step toward ensuring long-term performance, safety, and value in your industrial applications. A dependable manufacturer will not only deliver gratings that meet stringent quality and compliance standards but also provide the technical expertise and flexibility needed to address specific operational challenges. From material selection and structural integrity to timely delivery and post-sales support, the right partner can significantly enhance the efficiency and reliability of your infrastructure—especially in demanding sectors like oil, chemical, and marine industries.